Click to enlarge

Features

- −40°C to +200°C

- Temperature stability ±0.01°C

- Mini enclosure for purge with dry/inert gas

- Compatible to standard sample tray of the Agilent G200/XP

- Available for other commercial nanoindenters upon request

Heating and Cooling for Nanoindentation

Mechanical properties measured with nanoindentation techniques are frequently very sensitive to temperature. For some application, also temperatures below 0°C have to be accessible.

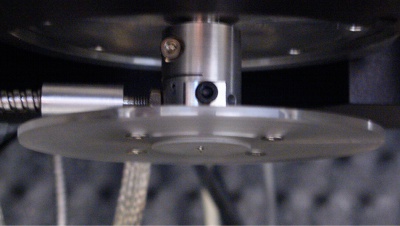

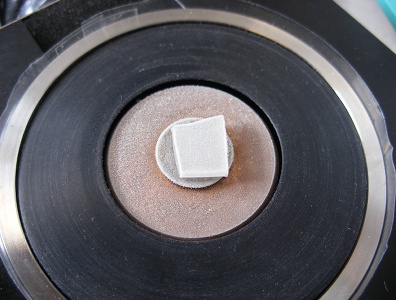

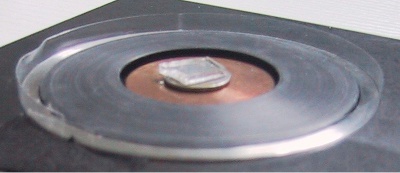

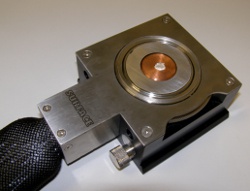

SURFACE offers a flexible heating/cooling system which covers a temperature range from −40°C to +200°C (not continuously, see specifications below). The sample holder is compatible to the standard sample tray of the Agilent G200/XP nanoindenters (other brands/models upon request). The system also includes a two-piece cover plate for mounting to the XP head. A big transparent polycarbonate plate covers the whole sample tray during the measurement, and a smaller center plate is adjusted to create a secure parking position for the indenter tip.

The Sample Enclosure

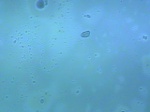

When cooling a sample below the dewpoint of the ambient air, it is essential to avoid condensation and ice formation on the sample surface. To achieve this, a flexible wall surrounds the heating/cooling table. Together with the cover plate, this forms a small environmental chamber that can be purged with dry or inert gas.

The temperature range, stability (±0.01°C), and enclosure make the SURFACE heating/cooling stage ideally suited for:

−31°C, inert gas 2 s off

Click to enlarge

−31°C with inert gas purge

Click to enlarge

- Polymer research

- Biological research

- Medical research

- Construction material research

Biological Research

For biological and medical research applications, the system can be shipped as a temperature controlled liquid cell.

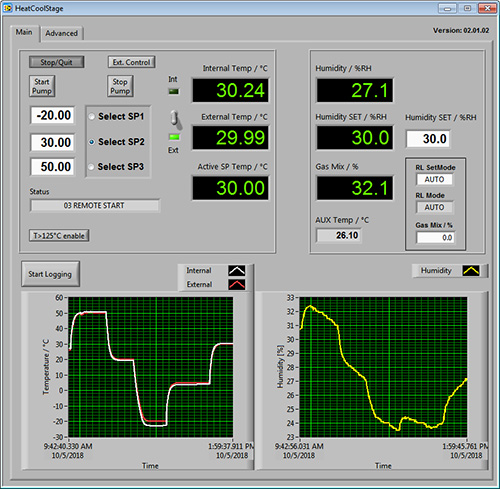

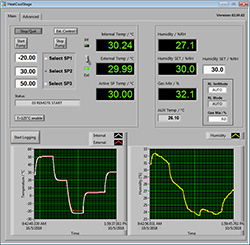

Optional: useable with SURFACE Humidity Controller

Click to enlarge

- Purging gas flow can be combined with humitity controller

- Controlling temperature and humidity at sample location

- Combined software interface for temperature and humidity

- Humidity range: 0...90 % RH, depending on temperature

- Temperature range of humidity sensor: -40...+125 °C

Specifications

| Compatibility: | Agilent G200/XP compatible sample tray, contact us for other brands/models |

| Sample size: | max. 25 mm diameter |

| Heating: | 200°C* |

| Cooling: | −40°C* |

| Temperature stability: | ±0.01°C |

| Temperature sensor: | 2 sensors, one PT100 integrated into the sample stage, one PT100 located in the cooling/heating bath |

| Purge: | Integrated inert gas purge system (e.g. Ar) |

| Controller: | Self-tuning PID controller |

| Interface: | RS-232 |

| Pump: | 22–26 l/min |

| Connection: | 2 m hose connection to stage |

| Power requirements: | 230 VAC, 2000 W |

*) max./min. temperatures depend on the circulation/bath liquid used. To reach −40°C, a special low viscosity liquid is used which reduces the upper limit to 180°C.