MTS XP Nanoindenter

MTS G200 Nanoindenter

Two high performance nanoindenters are available for testing at loads up to 10 Newton at nm displacement and nN force resolution. The instrumentation provides access to:

- Hardness and Young's modulus as a function of indentation depth

- Scratch and wear testing

- Adhesion of films on substrates

- Micro bending and compression

- Dynamic testing of polymers

- Temperature dependent tests

- Fracture toughness

The patented continuous stiffness technique (CSM) yields the respective values for each point of the measurement throughout the whole loading cycle and enables dynamic experiments to characterize the time dependent mechanical behavior of the sample.

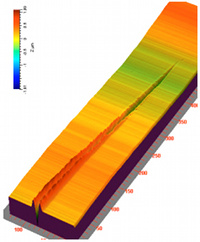

Scratch test

Scratch tests provide information about the wear resistance of surfaces as well as the interfacial adhesion between coatings on a substrate. Interactive scanning allows characterizing the indent and scratching geometries in the nanometer scale and to position indents within several nanometers.

For temperature dependent testing our nanoindenters are equipped with heating/cooling stages and laser heaters. Sample properties can be determined at temperatures up to 500°C.