The PLD Deposition Automation Software

All SURFACE PLD systems are highly automated to control the whole deposition process. This ensures easy operation of the system. The PlumeMaster software is based on the proven Windows XP Professional operating system. It is optimized for PLD system control and offers advanced deposition features.

PlumeMaster Features

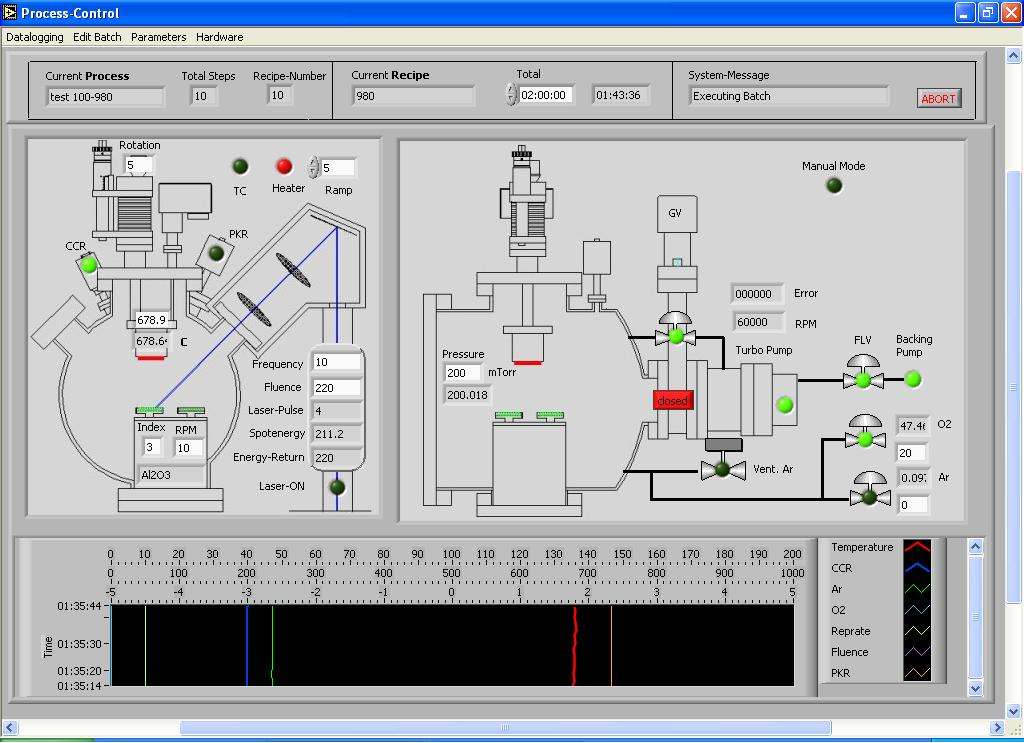

Overview Screen

Click to enlarge

- Control of the full system: Vacuum, gas flow, substrate manipulator/heater, target manipulator, laser

- flexible, intuitive user interface

- advanced settings for full control over all parameters

- multilayer capability with automated target change, superlattice growth

- control of gas flow/pressure range for each deposition step

- annealing steps at defined chamber gas fill, even between deposition steps

- laser energy calibration before each deposition step

- full data logging and display

- PLD target tracking for even wear of target surface – the target can automatically be moved in a way that equalizes the number of laser pulses per target surface area

- for heaters without thermocouple in direct substrate contact: heater temperature compensation to correct temperature readings obtained from the heater thermocouple

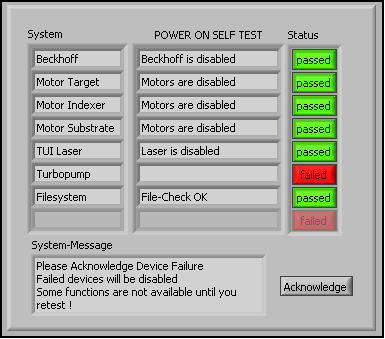

- system self-test capabilities

- support of SURFACE Fluence Control for perfect reproducability

- multi-user capable with built-in user management

Easy Process Programming

Recipe editor

Click to enlarge

Each process basically represents a list of deposition or annealing recipes. These recipes are easily defined in an easy-to-use dialog. Recipes can be reused, the right target material will be found and used even if its position in the target cassette has been changed.

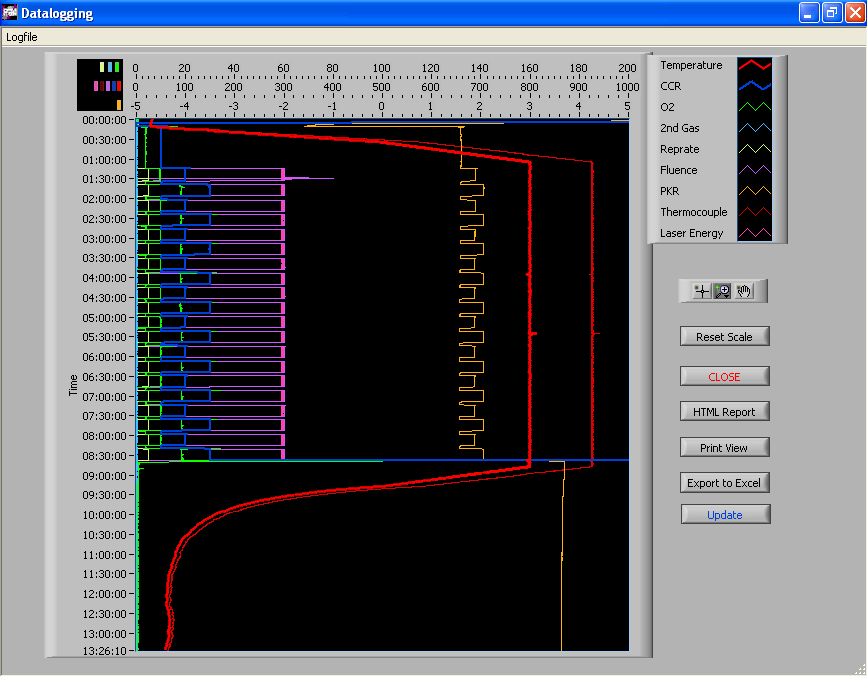

Advanced data logging

Data log plot

Click to enlarge

Automatically during each process, or manually while the system is idle, PlumeMaster logs all relevant system data. This facilitates troubleshooting end ensures perfect documentation of your experiments.

The logged data can easily be plotted and zoomed right within PlumeMaster